let's keep thinking about the future!

2025

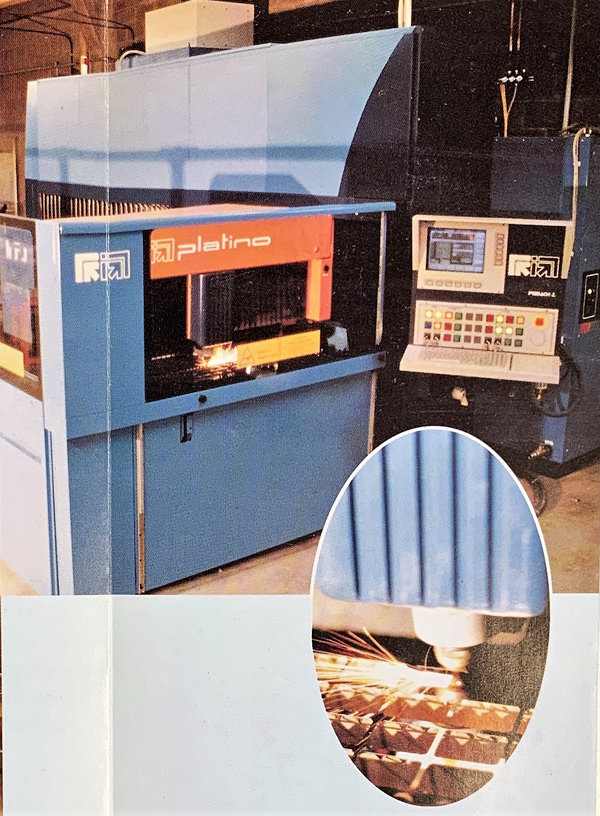

For our 70th birthday, we present ourselves with a new Platinum Linear Fiber Laser and a new high-tech Vimercati bending machine, equipment that immediately propels us into the future!

2024

Sergio's daughter Marta joins the company, further consolidating the presence of the fourth generation of the family in the business.

2023

We obtain UNI EN ISO 9001:2015 quality certification, as well as UNI EN ISO 3834-2:2021 and UNI EN 15085-2:2020 welding certification.

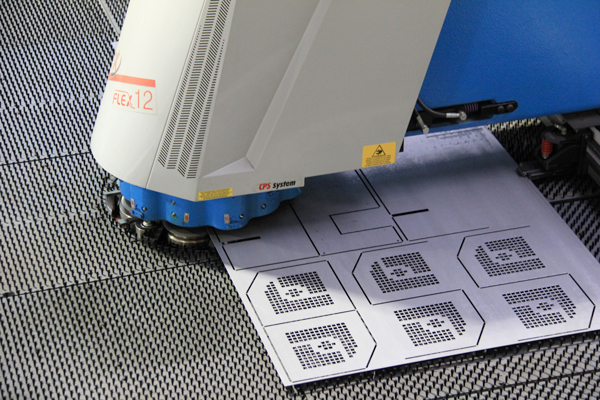

To complement the bending department, we have invested in a new high-tech piece of machinery: the brand new BCe 2720 panel bender from Prima Power, a fully automatic bending machine. It is a non-hydraulic, fast and accurate bending solution that guarantees productivity, precision, repeatability and reliability.

Simone, Claudia's son, also joins the company, consolidating the presence of the 4th family generation in the business.

With a new expansion of the production plant, 3500 m² is exceeded.

With the arrival of Samuel, Sergio's son, the 4th generation joins the company.

New "fiber laser" technology is also adopted by attaching a second new machine to the automatic warehouse. The bending department now numbers 5 machines. A further expansion of the plant is completed.

2016

4.0 industry forerunners we introduce IT management system connected to important plants and able to detect all cycle times of each employee using bar codes

2015

In the 60th anniversary of the company we give ourselves the future! A fully automatic warehouse with more than 100 drawers that powers a new 4000 watt laser

2013

The water jet system break down all limit, and it's now possible to cut any kind of material

2011

A further expansion is requested by the new and important investments in the years to come

2010

New indexed trowel punching machine capable of performing various shape processes such as edgings, folds and threads

2007

Automation and new technologies require an important increase of spaces, and the neighboring warehouse is annexed

2006

A new laser system is connected to a 10-drawer tower warehouse that can feed the machine without supervision

2003

Sergio and Claudia take over the management of the company from their parents. A new 135 ton bending machine is installed and the bending department can count on three presses: 2, 2.5 and 3m

2001

The partnership with Prima Industrie is strengthened by replacing the first laser with a 2500 watt double board system

1996

Laser process breaks down in the sheet metal transformation processes, and our first 1500 watt plant is installed

1994

Replaced the punching machine with a more performing plant. Design and programming are made with a CAD-CAM system. The headquarters doubles, with the acquisition of a new building

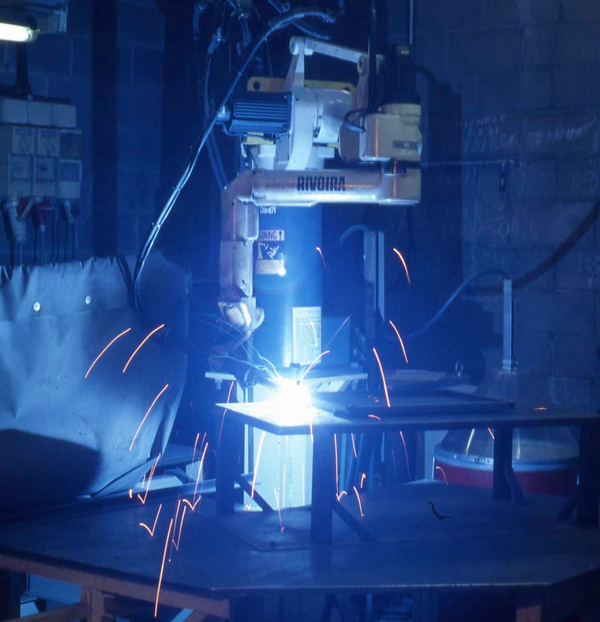

1992

Introduction of an innovative robotic welding site

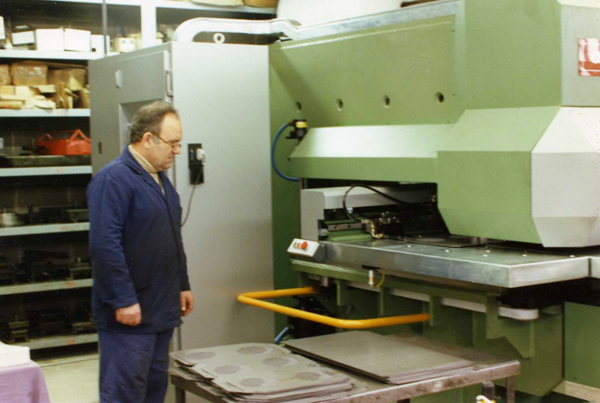

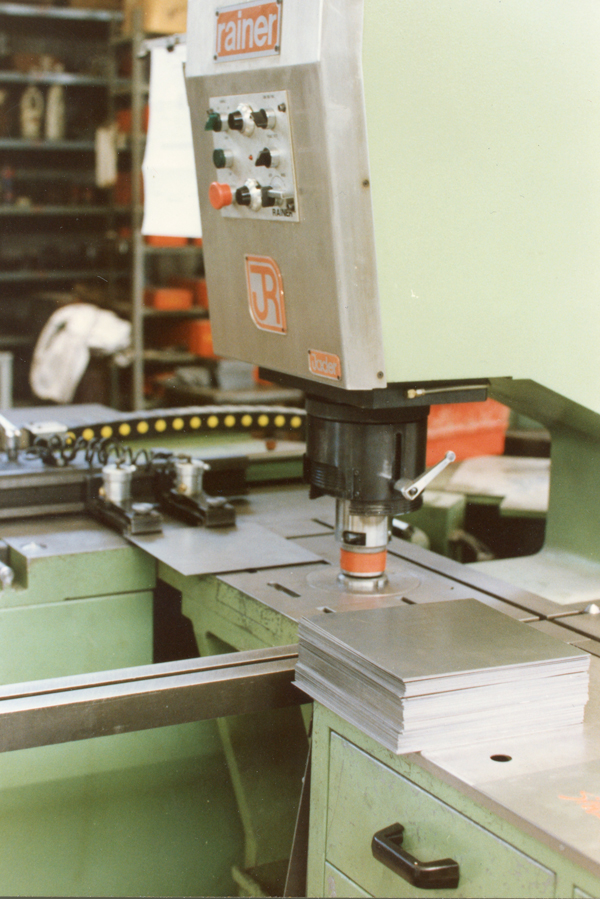

1988

The first Rainer 2009 numerical control punching machine is installed

1987

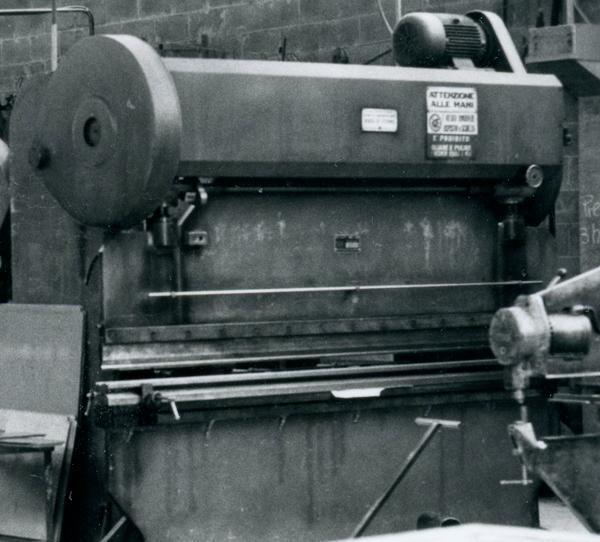

The first Colgar numerical control folder is installed

1984

In the early 1980s the third generation joined the company and a targeted process of technological renewal begins

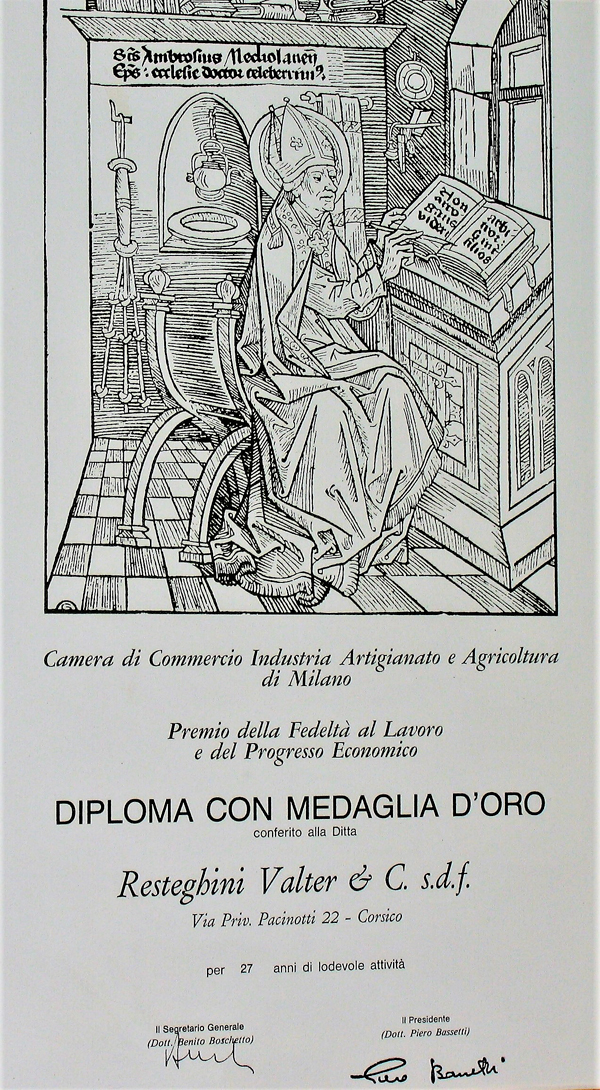

1982

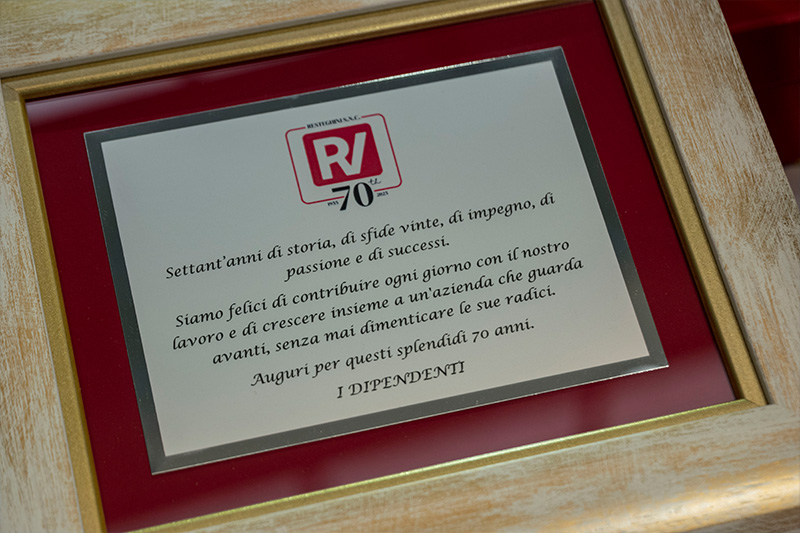

The Milan Chamber of Commerce awarded the company with the "Work Loyalty Award"

1978

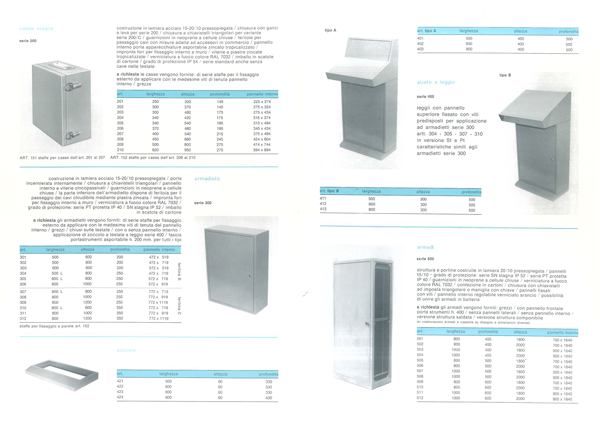

A catalog of frames, lecterns and cabinets for our electrical equipment is published

1974

The company moved to a new industrial settlement built in Via Pacinotti in Corsico

1969

Due to the production of cabinets for electrical panels with big dimensione, a further expansion of the production has been carried out.

1964

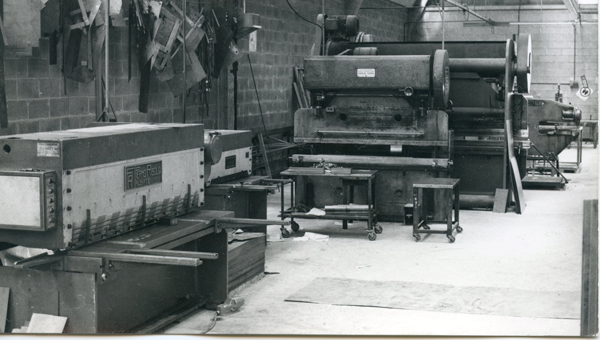

The business thrives and a new expansion in Via Pestalozzi in Milan is necessary to install the first mechanical shearing and folding machines

1958

As Valter, the founder's son, joined the company, a new and bigger space was found in via Franco Tosi in Milan. Expanding the small company was necessary to introduce the production cycle machines for manual cutting and folding.

1955

Bruno Resteghini, an expert tinsmith, begin the activity in Via Canonica in Milan. In a small shop, metal products for the food, telephone and electrical equipment industries are welded and finished. The limited space doesn't allow to cut and bend the metal sheet tht are outsorced.